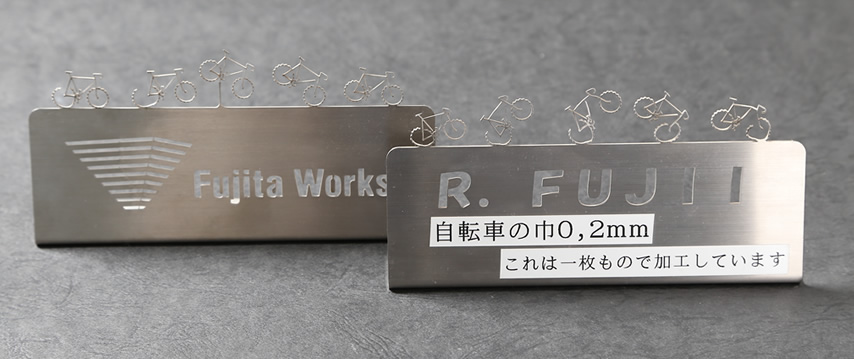

技術紹介

世界が認める、技。

藤田ワークスの精密板金加工は、高度なテクノロジーを駆使しています。

最新鋭の加工設備を随時導入・更新し、お客様のニーズにきめ細かに対応しています。

私たちは、試行錯誤の繰り返しの中で確かなノウハウを蓄積、薄板TIG溶接をはじめ、他では真似のできない製品加工を次々と開発・実現しています。

特に、半導体や液晶製造装置向けの精密板金加工においては、100μm超薄ステンレス溶接や、溶接後の絞り加工も可能な数百ミクロン厚のステンレス溶接など、板金加工の技に加え、プラント業界向けのニッケルやチタン材料を使用した製品加工分野では世界シェアを獲得しています。

2006年には経済産業省「元気なモノ作り中小企業300社」を板金業界から唯一選ばれるなど、国内外から認められ評価されています。

実績紹介

機械加工から板金加工へ [H7精度の加工]

これまでは機械加工でした。

当社のレーザー加工は、考え方を変えるものです。

この加工は、嵌め合い交差がH7を実現しています。

![機械加工から板金加工へ [H7精度の加工]](https://fujitaworks.com/wp-content/uploads/2020/03/pht_jisseki_01.jpg)

薄板溶接の極み [SUSt0.6mm]

どこにも出来ませんでした。

当社は、TIG溶接で板厚0.6mmの連続・裏波溶接を実現。

絞り加工があっても割れません。

![薄板溶接の極み [SUSt0.6mm]](https://fujitaworks.com/wp-content/uploads/2020/03/pht_jisseki_02.jpg)

異種金属5層同時接合

抵抗溶接によるチタン、ニッケル、鉄の5層材料の同時接合を実現しました。

深絞りをせずに加工

量産時は金型を製作し加工するものですが、開発日数を削減し、しかも低コストで製品を製作します。

製品は、曲げ構造にて実現。

設備のスペック外加工 [最小径加工]

設備スペックの最小パイプ加工径よりも小さいパイプを加工。

Φ10㎜のニッケル材料を加工しています。

![設備のスペック外加工 [最小径加工]](https://fujitaworks.com/wp-content/uploads/2020/03/pht_jisseki_05.jpg)