Technology Information

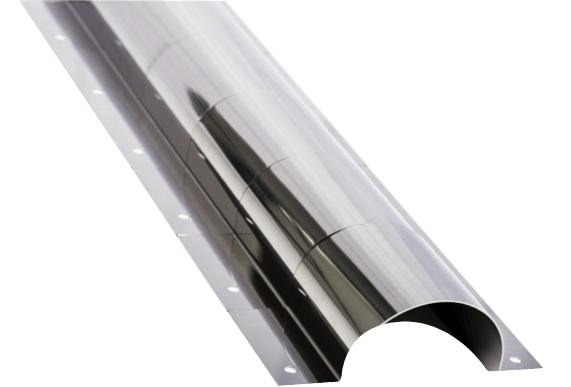

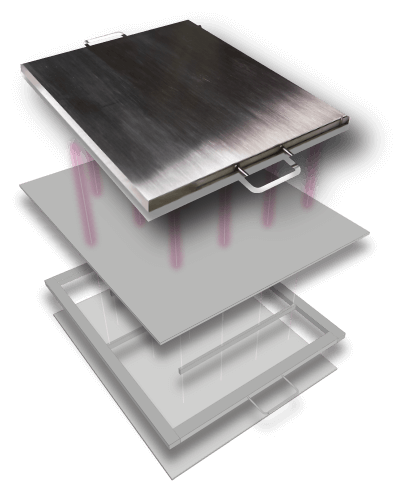

The precision sheet metal processing of the FUjita Works utilizes high technology. We introduce the newest metal processing equipment on a timely basis and update it to fulfill precisely our customer’s requirements.

By repeating the cut-and-try method, we have accumulated the reliable know-how to develop and achieve unsurpassed precision metal processing techniques, such as thin-sheet TIG welding that are ideal for the semiconductor or liquid crystal manufacturing equipment. It lets us perform 100 μm ultra-thin stainless welding and stainless welding of a few hundred. Moreover, we have earned a share of the worldwide market for product processing using Nickel or Titanium for the plant market.

The Fujita Works was selected in 2006 by the Ministry of Economy, Trade and Industry as one of \”The introducing 300 of Japan’s Exciting Monozukuri (Product Manufacturing) SEMs\”. Fujita Works is committed and its technology is highly regarded, not only in Japan, but also throughout the workd.